Peer-reviewed Publications (40 papers, 4 book chapters, 24 patents)

Submitted

8. R. Venkataswamy, L. Trimble, A. McDonald, D. Nevers, L. V. Bengochea, A. Carswell, A. Rossner*, J. Seo*, Environmental Impact Assessment of Chemical Mechanical Planarization Consumables: Challenges, Future Needs, and Perspectives, Submitted.

7. R. Venkataswamy, L. Trimble, S. Ryu, N. Le, K. Park, H. Kang, J. Seo*, Atomic-Level Insights into CeO2 Performance: Chemical Interactions in CMP Explored through CeO2-SiO2 Studies, Submitted.

6. H. Tran, J. Guchovi, J. Commane, E. J. Podlaha, J. Seo*, Examining Amino Acids as Environmentally Friendly Corrosion Inhibitors for Cu and Co Chemical Mechanical Planarization, Submitted.

5. V-T. Nguyen, J. Wait, T. Nishi, S. Hamada, H. Himaya, and J. Seo*, Systematic Root Cause Analysis of Ceria-Induced Defects during Chemical Mechanical Planarization and Cleaning, Submitted.

4. S. Park, J. Seo*, Comparative First-Principles Analysis of Crystalline vs. Amorphous CeO2 Particles: Implications for Chemical Mechanical Planarization, Submitted.

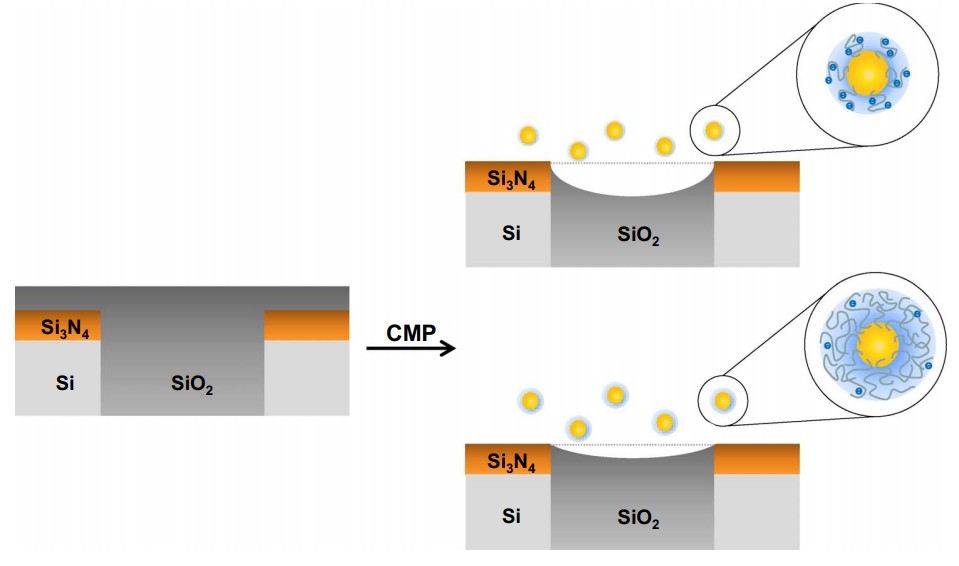

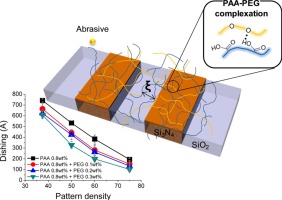

3. S. Choi, J. Yim, J. Lim, S. Kim, Y. Jeong, K. Bae, J. Seo*, K. Lee*, Tailored electrostatic attraction force between anionic polymer and Si3N4 film in consecutive gate poly open CMP, Submitted.

2. A. Othman+, A. Gowda+, D. Andreescu, M. Hassan, S. Babu, J. Seo*, S. Andreescu*, Two decades of ceria nanoparticles research: structure, properties and emerging applications, Submitted.

1. M. Park, S. Woo, J. Seo, J. Choi, E. Jeong, P.J. Kim, Directing the uniform and dense Li deposition via graphene-enhanced separators for high-stability Li metal batteries, Submitted.

2024

41. A. Venkataronappa, J. Bankaitis, J. Seo*, Enhancing Dispersion Stability and Recyclability of Ceria Slurry with Polyacrylic Acid for Improved Glass Polishing Performance, Journal of Industrial and Engineering Chemistry, 2024, Accepted.

40. J. Seo, S. Ryu, J. Kwon, K. Lee*, Structural Dependency of Pyridine Carboxylic Acid Isomers in Metal-Organic Coordination Adsorption, Applied Surface Science, 2024, Accepted.

39. J. Seo, J. Hur, S. Kim, Y. Kim, Y. Kim, K. Bae, K. Lee*, and G. An*, Recovery and Reuse of Magnetic Silica-Coated Iron Oxide Particles for Eco-Friendly Chemical Mechanical Planarization, Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2024, Accepted.

38. M. Liu, B. Zhang*, J. Seo*, W. Xian, D. Cui, P. Wu, Y. Wang, S. Liu, Development of Highly Stable Ceria Slurry in Acetic Acid-Ammonium Acetate Buffer System for Effective Silica Chemical Mechanical Planarization, Materials Science in Semiconductor Processing, 2024, 108411.

37. D. Lee+, S. Lee+, D. Jung, K. Roh, J. Seo, J. Kim, K. Kim, P.J. Kim*, J. Choi*, Synergistically Enhanced LiF-rich Protective Layer for Highly Stable Silicon Anodes, Applied Surface Science, 2024, 160023.

36. A. Othman, H. Kim, R. Trivedi, T. Kulasingam, J. Seo*, Understanding and Mitigating Temperature-Induced Agglomeration in Silica-based Chemical Mechanical Planarization (CMP) Slurry Storage, Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2024, Accepted.

35. K. Kwon, J. Kim, S. Han, J. Lee, J. Kwon, J. Lee, J. Seo, P.J. Kim*, T. Song*, J. Choi*, Low-Resistance LiFePO4 Thick Film Electrode Processed with Dry Electrode Technology for High-Energy-Density Lithium-Ion Batteries, Small-Science, 2024, 2300302.

34. S. Yang, J. Kim, S. Lee, J. Seo, J. Choi*, P.J. Kim*, Uniform Li Deposition through the Graphene-Based Ion-Flux Regulator for High-Rate Li Metal Batteries, ACS Applied Materials & Interfaces, 2024, 16, 3, 3416-3426.

2022

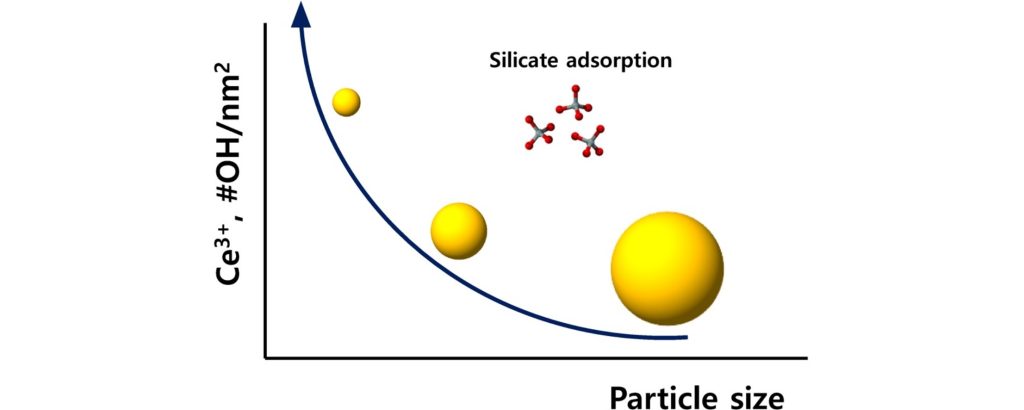

- 33. K. Lee, S. Kim, S. Sun, G. Lee, J. Kwon, J. Hwang, J. Seo, U. Paik, T. Song, Hydrogenated Ceria Nanoparticles for High-Efficiency Silicate Adsorption, New J. Chem, 2022.

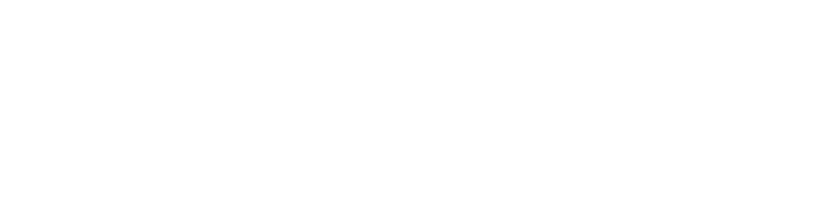

- 32. J. Seo*, K. Kim, H. Kang, S.V. Babu, Perspective-Recent advances and perspectives on ceria particle applications in chemical mechanical planarization, ECS Journal of Solid State Science and Technology, 2022, 11, 084003. (Perspective article)

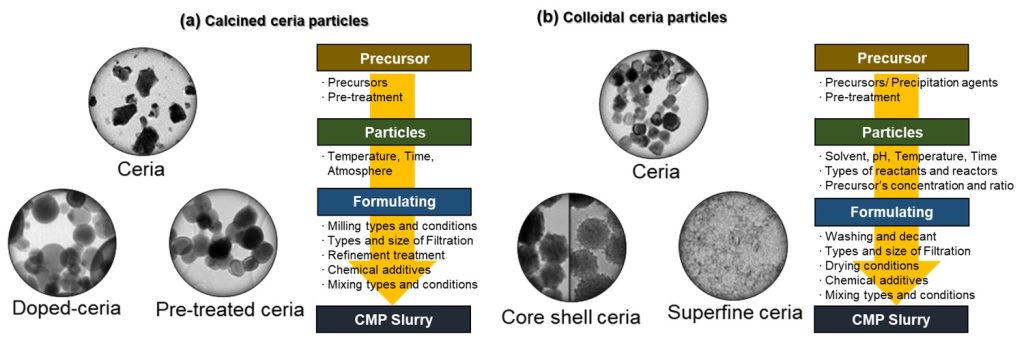

- 31. C. K. Ranaweera, S.V. Babu, S. Hamada, J. Seo*, Measurement of the force required to move ceria particles from SiO2 surfaces using lateral force microscopy, Journal of Materials Research, 2022.

- 30. K. Lee, J. Seo, Suppression of Dissolution Rate via Coordination Complex in Tungsten CMP, Applied Sciences, 2022, 12(3).

2021

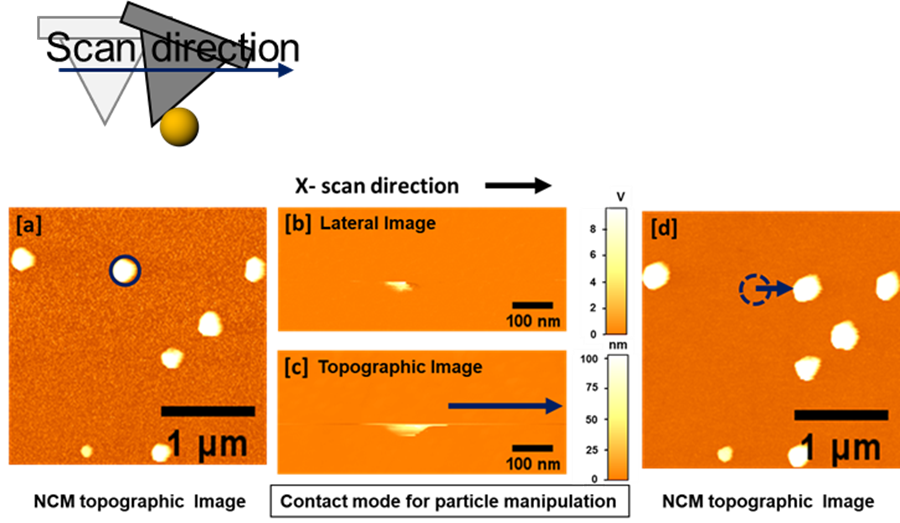

- 29. J. Seo*, A. Othman, H. J. Kim, J. Devabhaktuni, R. Trivedi, D. Penigalapati, T. Kulasingam, H. Vegi, S. V. Babu, Storage Temperature Effects on the Slurry Health Parameters and SiO2 Removal Rates during Chemical Mechanical Polishing, ECS Journal of Solid State Science and Technology, 2021, 10, 104002.

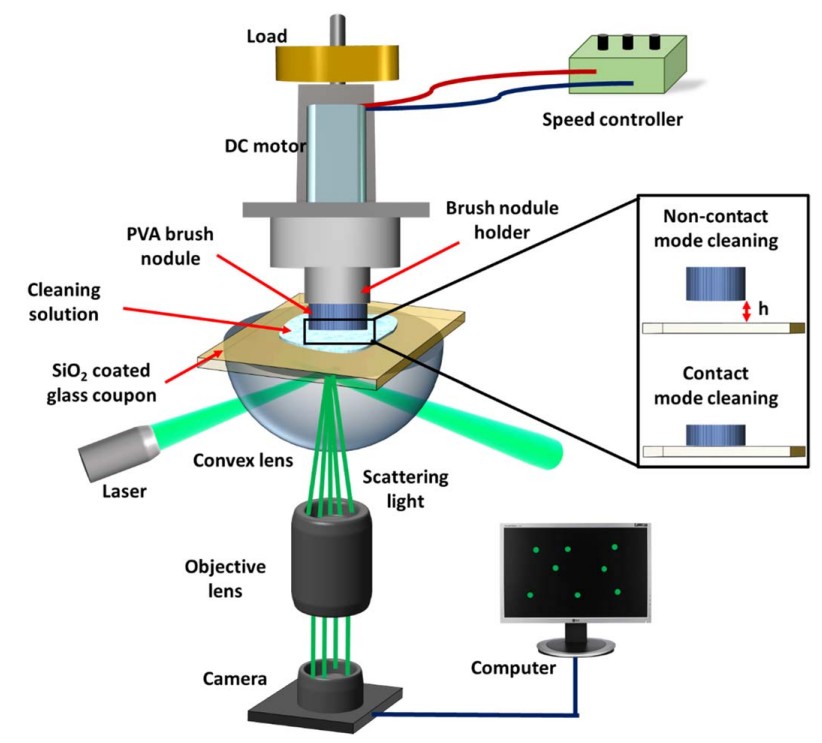

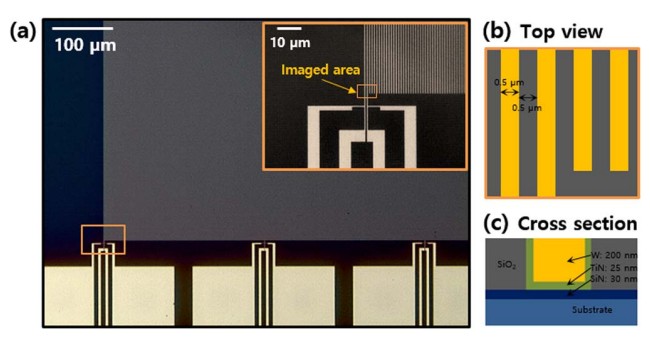

- 28. C. K. Ranaweera, P. Khajornrungruang, S. Hamada, A. Gowda, H. Vegi, J. Seo*, and S.V. Babu, Real-Time Visualization of the Cleaning of Ceria Particles from Silicon Dioxide Films Using PVA Brush Scrubbing, ECS Journal of Solid State Science and Technology, 2021, 10, 084004.

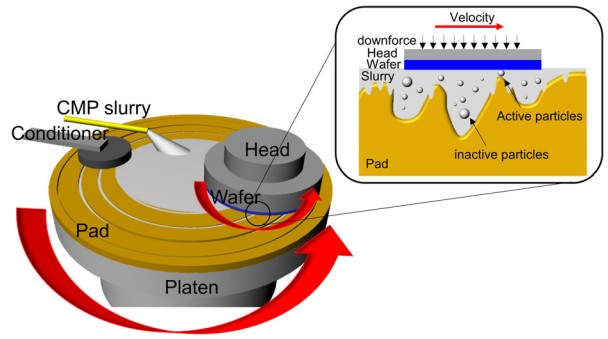

- 27. J. Seo*, A review on chemical and mechanical phenomena at the wafer interface during chemical mechanical planarization, Journal of Materials Research, 2021, P1-23. (Review article), Early Career Scholars in Material Science

2020

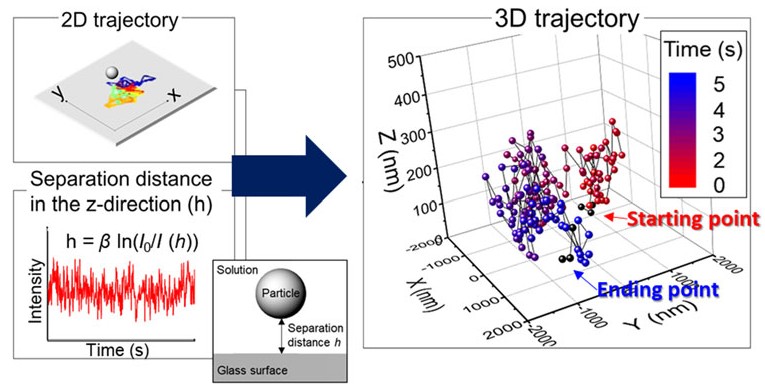

- 26. J. Seo (Corresponding)*, A. Gowda*, P. Khajornrungruang, S. Hamada, and S.V. Babu, 3D Trajectories and Diffusion of Single Ceria Particles near a Glass Surface and their Removal, Journal of Materials Research, 2020, P1-10. Early Career Scholars in Material Science

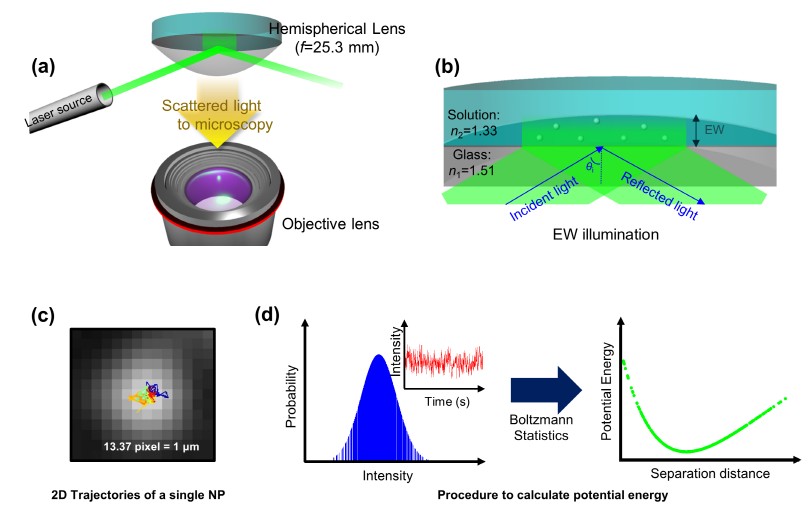

- 25. J. Seo (Corresponding)*, A. Gowda*, P. Khajornrungruang, S. Hamada, T. Song, and S.V. Babu, Trajectories, Diffusion, and Interactions of Single Ceria Particles on a Glass Surface Observed by Evanescent Wave Microscopy, Journal of Materials Research, 2020, 35 (3), P321-331.

- 24. A. Gowda, J. Seo, C.K. Ranaweera, S.V. Babu, Cleaning Solutions for Removal of ∼30 nm Ceria Particles from Proline and Citric Acid Containing Slurries Deposited on Silicon Dioxide and Silicon Nitride Surfaces, ECS Journal of Solid State Science and Technology, 2020, 9 (4), 004013.

2019

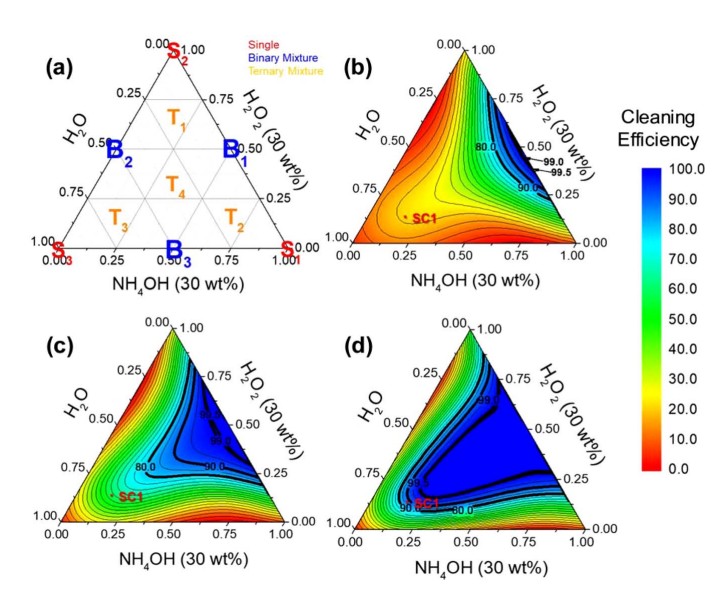

- 23. J. Seo (Corresponding), S.S.R.K.H. Vegi, S.V. Babu, Post-CMP Cleaning Solutions for the Removal of Organic Contaminants with Reduced Galvanic Corrosion at Copper/Cobalt Interface for Advanced Cu Interconnect Applications, ECS Journal of Solid State Science and Technology, 2019, 8 (8), P379-P387.

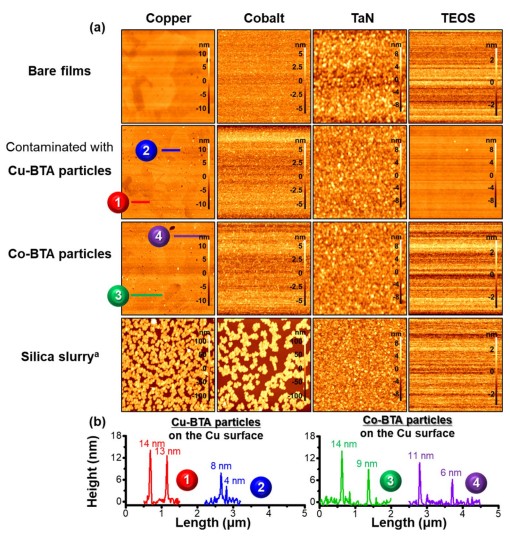

- 222. J. Seo, S.S.R.K.H. Vegi, C.K. Ranaweera, N.K. Baradanahalli, J. Han, D. Koli, S.V. Babu, Formation of Cobalt-BTA Complexes and Their Removal from Various Surfaces Relevant to Cobalt Interconnect Applications, ECS Journal of Solid State Science and Technology, 2019, 7 (5), P3009-P3017.

2018

- 21. J. Seo, A. Gowda, S.V. Babu, Almost Complete Removal of Ceria Particles Down to 10 nm Size from Silicon Dioxide Surfaces, ECS Journal of Solid State Science and Technology, 2018, 7(5), P23-P252.

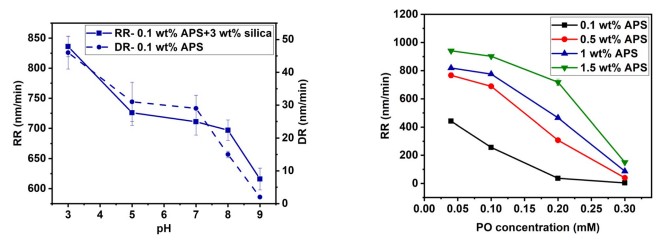

- 20. C.K. Ranaweera, N.K. Baradanahalli, R. Popuri, J. Seo, S.V. Babu, Ammonium persulfate and potassium oleate containing silica dispersions for chemical mechanical polishing for cobalt interconnect applications, ECS Journal of Solid State Science and Technology, 2018, 7 (5), P1-P8.

- 19. J. Choi*, J. Kim*, J. Seo, J. Kwon, T. Song, Environmentally-harmless Polylactic Acid-Polyethylene Glycol Binder for Deformable ceramic green body, Ceramics International, 2018, 44(4), 4220-4224. Front Cover

2014-2017 (18 papers)

- 18. J. Choi*, J. Kim*, J. Seo*, J. Kwon, T. Song, Toward functional 3D architecture platform: Advanced approach to anchor functional metal oxide onto 3D printed scaffold, Advanced Engineering Materials, 2017, 1700901. (Front Cover)

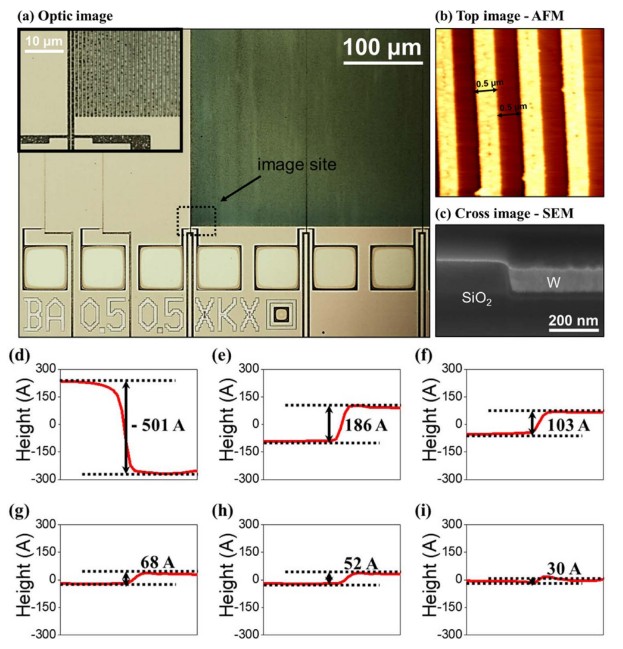

- 17. K. You*, J. Seo*, T. Song, Control of Tungsten Protrusion with Surface Active Agent during Tungsten Chemical Mechanical Polishing, ECS Journal of Solid State Science and Technology, 2017, 6(12), P822-P827.

- 16. J. Seo, K. You, J. Moon, J. Kim, U. Paik, Corrosion Behavior of Tungsten Metal Gate in the Presence of Hydrogen Peroxide at Acidic Medium, ECS Journal of Solid State Science and Technology, 2017, 6(4), P169-P171.

- 15. J. Seo, J. Kim, M. Lee, K. You, J. Moon, D. Lee, U. Paik, Multi-objective optimization of tungsten CMP slurry for advanced semiconductor manufacturing using a response surface methodology, Materials & Design, 2017,117, 131-138.

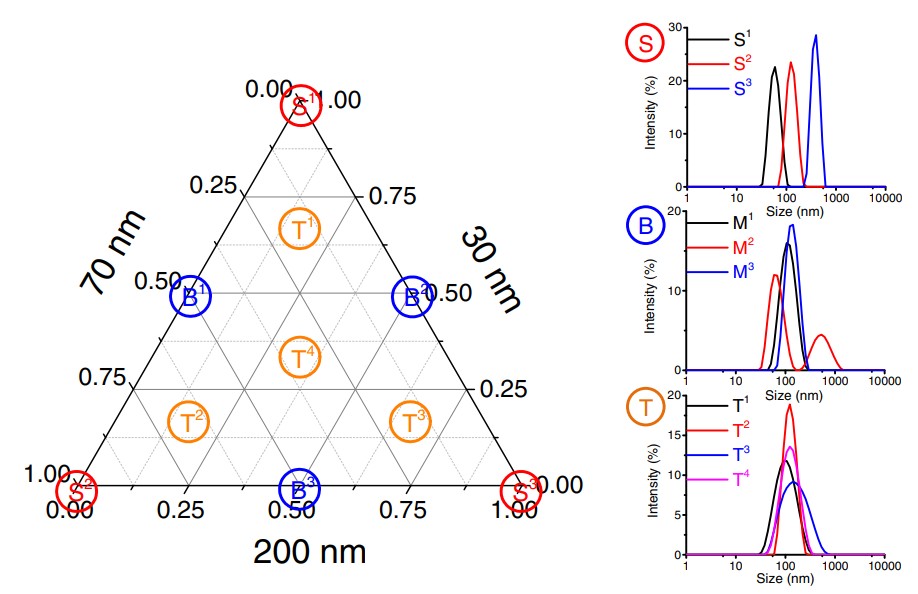

- 14. J. Seo*, J. Moon*, Y. Kim, K. Kim, K. Lee, Y. Cho, D. Lee, U. Paik, Synergistic Effect of Mixed Particle Size on W CMP Process: Optimization using Experimental Design, ECS Journal of Solid State Science and Technology, 2017, 6(1), P42-P44.

- 13. K. Kim*, K. Lee*, J. Seo, T. Song, Reduction of friction force between ceria and SiO2 for low dishing in STI CMP, ECS Journal of Solid State Science and Technology, 2017, 6 (10), P752-P754.

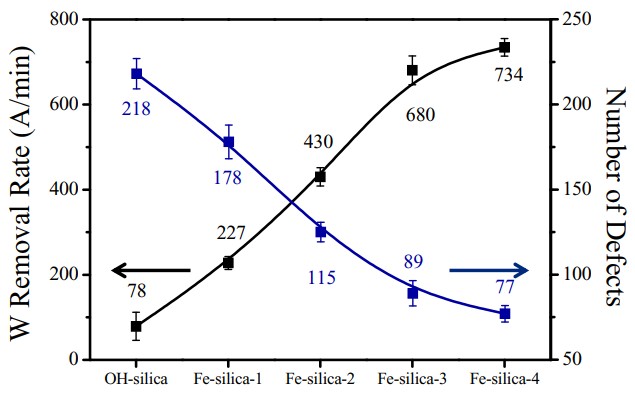

- 12. K. Kim, J. Seo, M. Lee, J. Moon, K. Lee, D. Yi, and U. Paik, Highly dispersed Fe3+-substituted colloidal silica nanoparticles for defect-free tungsten chemical mechanical planarization, ECS Journal of Solid State Science and Technology, 2017, 6 (7), P405-P409.

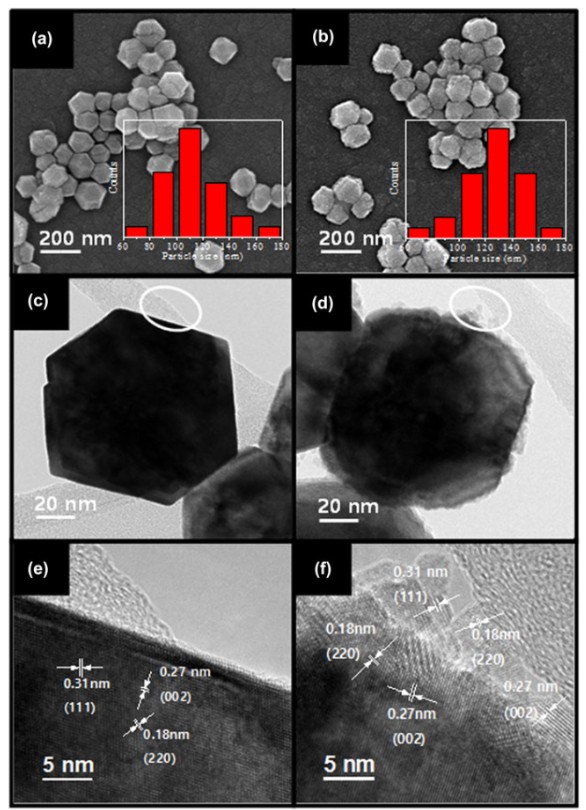

- 11. K. Kim, J. Seo, M. Lee, J. Moon, K. Lee, D. Yi, and U. Paik, Ce3+ enriched core-shell ceria nanoparticle for silicate adsorption, Journal of Materials Research, 2017, 32 (14), P2829-2836.

- 10. J. Kim, J. Seo, K. Fu, J. Choi, J. Kwon, L. Hu, U. Paik, Synergistic Protective Effect of a BN-Carbon-separator for Highly Stable Lithium Sulfur Batteries, NPG Asia Materials, 2017, 9 (4), e375.

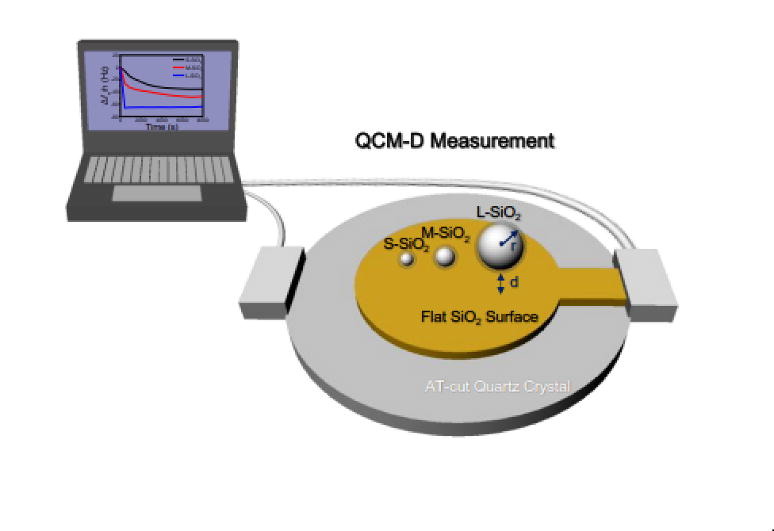

- 9. J. Seo, J. Kim, M. Lee, D. Yi, U. Paik, Size dependent interactions of silica nanoparticles with flat silica surface, Journal of Colloid and Interface Science, 2016, 483, 177-184.

- 8. J. Seo*, J. Moon*, J. Kim, K. Lee, J. Hwang, H. Yoon, D. Yi, U. Paik, Role of oxidation state of cerium on the ceria surfaces for silicate adsorption, Applied Surface Science, 2016, 389, 311-315.

- 7. J. Seo, D. Lee, K. Lee, K. Kim, K. Kim, Optimizing a blend of mixture slurry in chemical mechanical planarization for advanced semiconductor manufacturing using a posterior preference articulation approach to dual response surface optimization, Applied Stochastic Models in Business and Industry, 2016, 32, 648-659.

- 6. J. Kim, J. Seo, J. Choi, D. Shin, M. Carter, Y. Jeon, C. Wang, L. Hu, U. Paik, Synergistic Ultra-thin Functional Polymer Coated Carbon Nanotube Interlayer for High performance Lithium Sulfur Batteries, ACS Applied Materials and Interfaces, 2016, 8, 20092-20099.

- 5. J. Kim, J. Choi, J. Seo, J. Kwon, U. Paik, Two-dimensional Nafion nanoweb anion-shield for improved electrochemical performances of lithium-sulfur batteries, Journal of Materials Chemistry A, 2016, 4, 11203-11206.

- 4. J. Seo, J. Moon, S. Moon, U. Paik, Interpolymer complexes of poly (acrylic acid) and poly (ethylene glycol) for low dishing in STI CMP, Applied Surface Science, 2015, 353, 499-503.

- 3. J. Seo*, J. Lee*, J. Moon, W. Sigmund, U. Paik, Role of the surface chemistry of ceria surfaces on silicate adsorption, ACS Applied Materials and Interfaces, 2014, 6, 7388-7394.

- 2. J. Seo*, J. Moon*, J. Bae, K. Yoon, W. Sigmund, U. Paik, Control of adhesion force between ceria particles and polishing pad in shallow trench isolation chemical mechanical planarization, Journal of Nanoscience and Nanotechnology, 2014, 14, 4351-4356.

- 1. J. Seo*, K. Yoon*, J. Moon, K. Kim, W. Sigmund, U. Paik, Effects of physico-chemical properties between poly(ethyleneimine) and silica abrasive on copper chemical mechanical planarization, Microelectronic Engineering, 2014, 113, 50-54.

Book Chapters (Invited)

- J. Seo, Chapter 18. Challenges and solutions for post-CMP cleaning at device and interconnect levels, in Advances in Chemical Mechanical Planarization (CMP) 2nd edition, edited by S.V. Babu (2021).

- K. Lee, J. Seo, U Paik, Chapter 11. Preparation and characterization of slurry for CMP, in Advances in Chemical Mechanical Planarization (CMP) 2nd edition, edited by S.V. Babu (2021).

- J. Seo, CMP-related to contaminants: their source and characterization, in Emerging Contaminants, edited by Aurel Nuro (2020)

- J. Seo, U Paik, Preparation and characterization of slurry for CMP, Chapter 11 in Advances in Chemical Mechanical Planarization (CMP), edited by Prof. S.V. Babu (2016).

Patents

- Post-CMP cleaning composition, Japan, PCT/JP2022/026835 (Pending, 2022/07/06)

- Post-CMP cleaning composition, Japan, JP2023009994A (Pending, 2023/01/20)

- Post-CMP cleaning composition, Japan, JP2023009993A (Pending, 2023/01/20)

- High removal rate oxide film polishing slurry composition, Republic of Korea, 10-2021-0050246 (Granted, 2021/07/14).

- Abrasive particle of core-shell structure, preparing method of the same and polishing slurry composition comprising the same, Republic of Korea, 10-2019-0134621 (Pending, 2019/10/28).

- Polishing slurry composition, China, CN106661429B (Granted, 2019/07/05).

- Polishing slurry composition, Taiwan, TWI658133B (Granted, 2019/05/01).

- Slurry composition for chemical mechanical polishing, method of preparing the same, and polishing method using the same, USA, 15/293,816 (Granted, 2018/08/14).

- Slurry comprising for STI polishing, Republic of Korea, 1017617920000 (Granted, 2017/07/20).

- Polishing slurry composition, USA, US20170183537A1 (Pending, 2017/06/29).

- Slurry composition for chemical mechanical polishing, method of preparing the same, and polishing method using the same, Republic of Korea, 10-2017-0044522 (Pending, 2017/04/25).

- Polishing slurry composition, Republic of Korea, 1016820970000 (Granted, 2016/11/28).

- Slurry composition for chemical mechanical polishing, method of preparing the same, and polishing method using the same, China, CN106867411A (Pending, 2016/10/17).

- Polishing slurry composition, Republic of Korea, 1016603840000 (Granted, 2016/09/21).

- Porous polishing particle and slurry comprising the same, Republic of Korea, 1016558490000 (Granted, 2016/09/02).

- Nano ceria slurry composition for chemical-mechanical polishing and preparation method for thereof, Republic of Korea, 1016133590000 (Granted, 2016/04/11).

- Polishing slurry and substrate or wafer polishing method using the same, Republic of Korea, 1014067590000 (Granted, 2014/06/05).

- Polishing slurry and substrate or wafer polishing method using the same, Republic of Korea, 1014067600000 (Granted, 2014/06/05).

- Slurry composition and substrate or wafer polishing method using the same, Republic of Korea, 1014067570000 (Granted, 2014/06/05).

- Slurry composition and substrate or wafer polishing method using the same, Republic of Korea, 1014067580000 (Granted, 2014/06/05).

- Polishing slurry composition and substrate or wafer polishing method using the same, Republic of Korea, 1013881060000 (Granted, 2014/04/22).

- Polishing slurry for removal of initial step height and substrate or wafer polishing method using the same, Republic of Korea, 1013962520000 (Granted, 2014/05/12).

- Polishing slurry additive composition and slurry composition including the polishing slurry additive composition, Republic of Korea, 1020130134737 (Granted, 2013/11/07).

- Catalyst slurry, electrode prepared by using the catalyst slurry and fuel cell including the electrode, USA, US 8,512,905 (Granted, 2013/08/20).